Fighting dirt with laser

Oil, grease, dust, or drilling emulsion from production: None of this is allowed on the components during the final production step when assembling electric motors. A German vehicle manufacturer has therefore appointed PIA Automation to install a laser cleaning system in its e-motor plant - for high process reliability when cleaning the components with short cycle times.

When the e-motor, gearbox, high-voltage, and oil sump covers are joined together to form a single unit, the flange surfaces of the components must be absolutely clean. Even the smallest particles of oil, grease, dust or drilling emulsion on the surfaces can ensure that the aluminum components are not 100 percent sealed after assembly and bolting. For example, water can seep in and cause a short circuit. Until now, the vehicle manufacturer has carried out the cleaning process manually - with a cleaning cloth and alcohol solution. This is time-consuming for the employees and costs them a lot of working time, which they could actually use for more valuable work in the company. In addition, the responsibility of the employees when cleaning the parts is high: they decide when to change the cleaning cloths, for example, and visually check whether the components are clean or not.

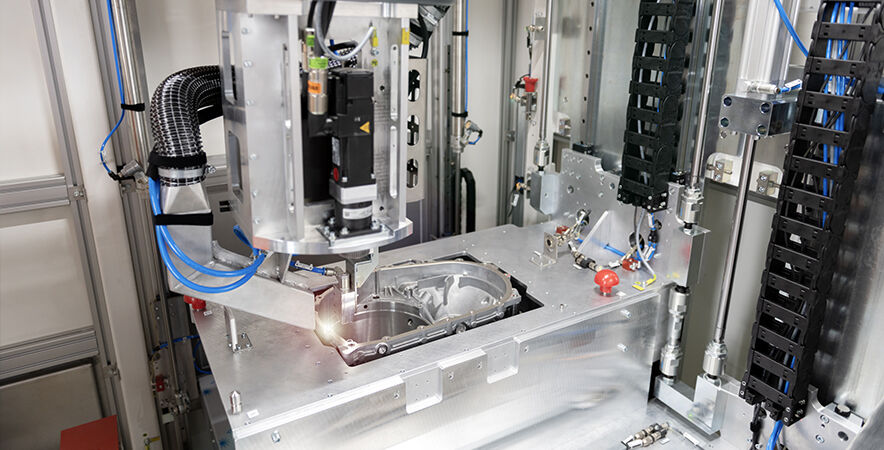

This important process step can be automated with a laser cleaning system. PIA also impressed the customer with its comprehensive expertise along the entire e-mobility value chain - and was awarded the contract. As the assembly system for the electric motors is already in operation, a second level for the cleaning cell was integrated in consultation with the customer and PIA's design engineers. A convincing solution: a lift system transports the components up to an intermediate level. There, a transfer system transports them to individual cleaning cells. The cleaning itself is carried out by a laser from Trumpf: a 6-axis robot with mounted optics is guided in such a way that it reaches the entire surface of the contours and cleans them quickly and reliably.

Laser cutting produces fumes. “The requirements for the extraction process are therefore also high,” says Markus Larcher, Sales Application Engineer at PIA. “The system needs to prevent the surfaces that have just been cleaned from being contaminated again by fume particles from the laser and also ensure that the air quality is guaranteed for employees in the entire system.” PIA therefore integrated a blowing and extraction device that blows the fumes into an extraction funnel immediately after cleaning.

A semi-automatic inspection process ensures consistently high cleaning quality. Employees of the OEM eject components and deliberately contaminate them at regular intervals. After cleaning these parts, a fluorescence measuring device checks whether the laser has reliably removed all the dirt.

The bottom line is that the vehicle manufacturer benefits from a significant increase in process reliability with laser cleaning - and the plain figures speak for themselves: the cycle time per component is just 28 seconds - including transport times. The cleaning time is around 15 seconds, and the laser cleans between 10 and 15 square centimetres per second.

“Automated cleaning with lasers proves how even supposedly small process steps can be automated reliably and economically,” says Larcher from PIA. The consistently high cleaning quality and short cycle time ensure a high level of customer satisfaction. It would be almost impossible for employees to achieve a similar level of cleaning quality manually, as the line produces very large quantities. In the future, the laser cleaning system will take the strain off employees, allowing them to concentrate on their actual tasks along the assembly line for electric motors.